History

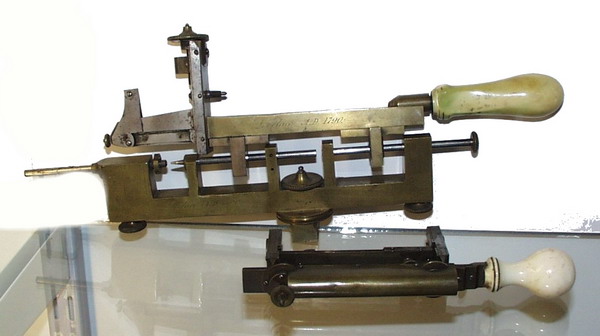

The original inventor of the topping tool is not known. It appeared sometime in the first half of the 19th century. An early version is the "machine à raboter" which used a straight file instead of a rotary cutter.

Machine à raboter Machine à raboter

Until around 1880 its primary use was by Swiss and other continental makers for shaping the tooth form of new watch wheels. The wheel blanks were cut on the wheel cutting engine, using a simple slitting saw. After mounting on the arbor, the wheel teeth were cut to shape on the topping tool.

English practice was to cut the wheels directly to form on the wheel cutting engine, so the topping tool was little used at that time.

From the 1880s cheaper and simpler tools became widely available from the tool sellers, and they were adopted by "jobbers" (repairers). They can be used in several ways by repairers/restorers.

A replacement wheel can rarely be found to exactly the right size, but it is a simple matter to select one that is too big and cut it down to size with the topping tool. A damaged wheel can often be corrected, or one that is too small can be stretched and the tooth form corrected by rounding up.

(The wheel must be correctly divided - rounding up tools follow the existing teeth, so they cannot correct for faulty dividing.)

Many different styles and sizes were made, but they are most commonly found in the smaller sizes. They continued to be offered in tool catalogues into the 1950s.

|